ALLRIDE 3D WP 16

WORLD’S FIRST WATERPROOF & 3D PRINTED BACKPACK

ALLRIDE 3D WP 16

Tax included. Shipping calculated at checkout

Delivery Time: 5-8 business days

Weatherproof 16 litre all-round backpack with incomparable 360° aircirculation

Description

Specifications

Facts

Manufacturer information

THE ULTIMATE ALL-ROUNDER

ALLRIDE 3D WP 16

THE WATERPROOF BIKE BACKPACK FOR EVERY ADVENTURE

Waterproof. Comfortable. Smart. The EVOC ALLRIDE 3D WP 16 is your go-to backpack for mountain biking, daily rides or spontaneous trail adventures – whatever the weather.Designed with the innovative 3D AIR PAD SYSTEM, this bike backpack offers next-level back ventilation and exceptional comfort.

The fully waterproof construction with welded seams and sealed zippers keeps your gear safe and dry – whether you're shredding single tracks or commuting in rainy weather conditions.

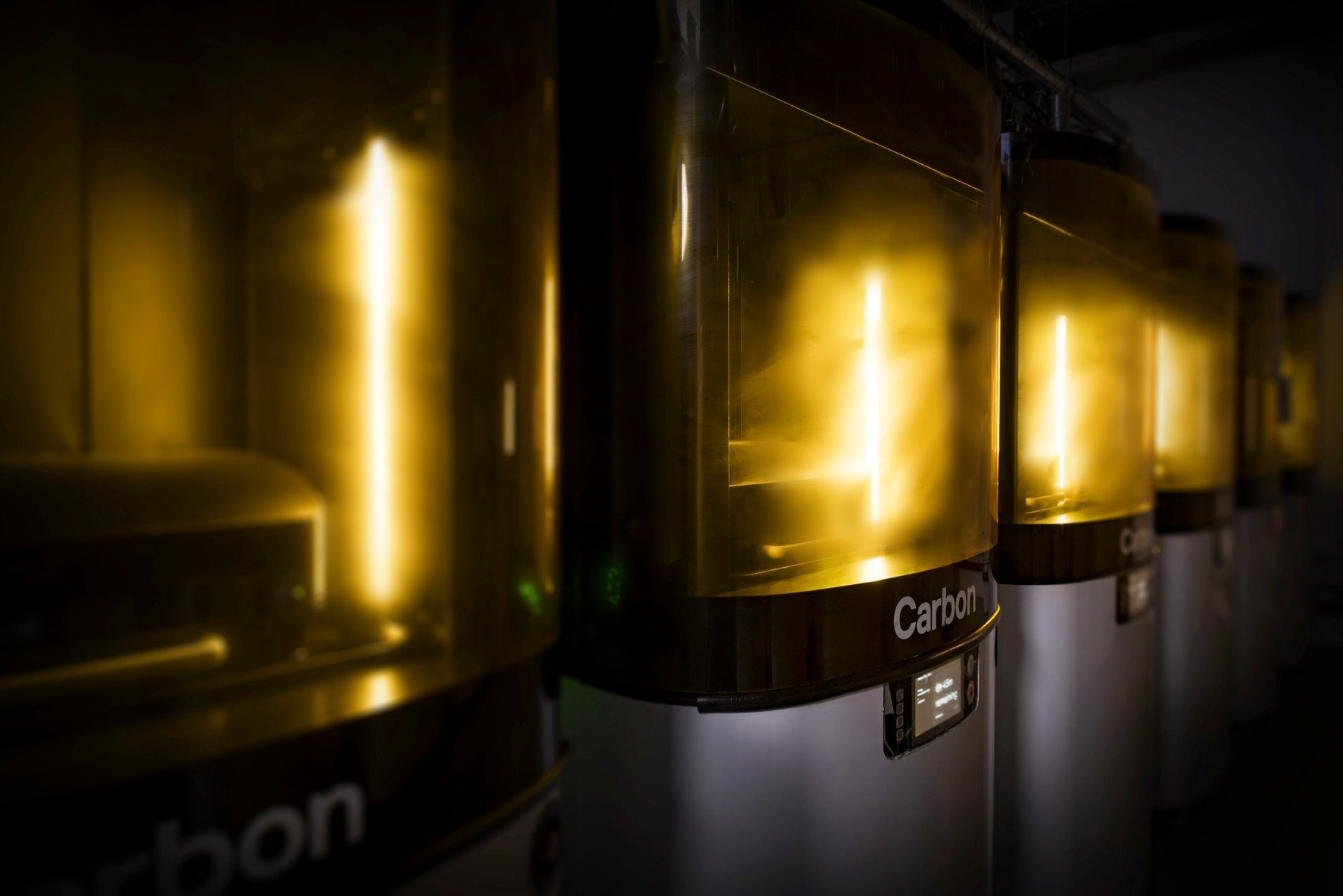

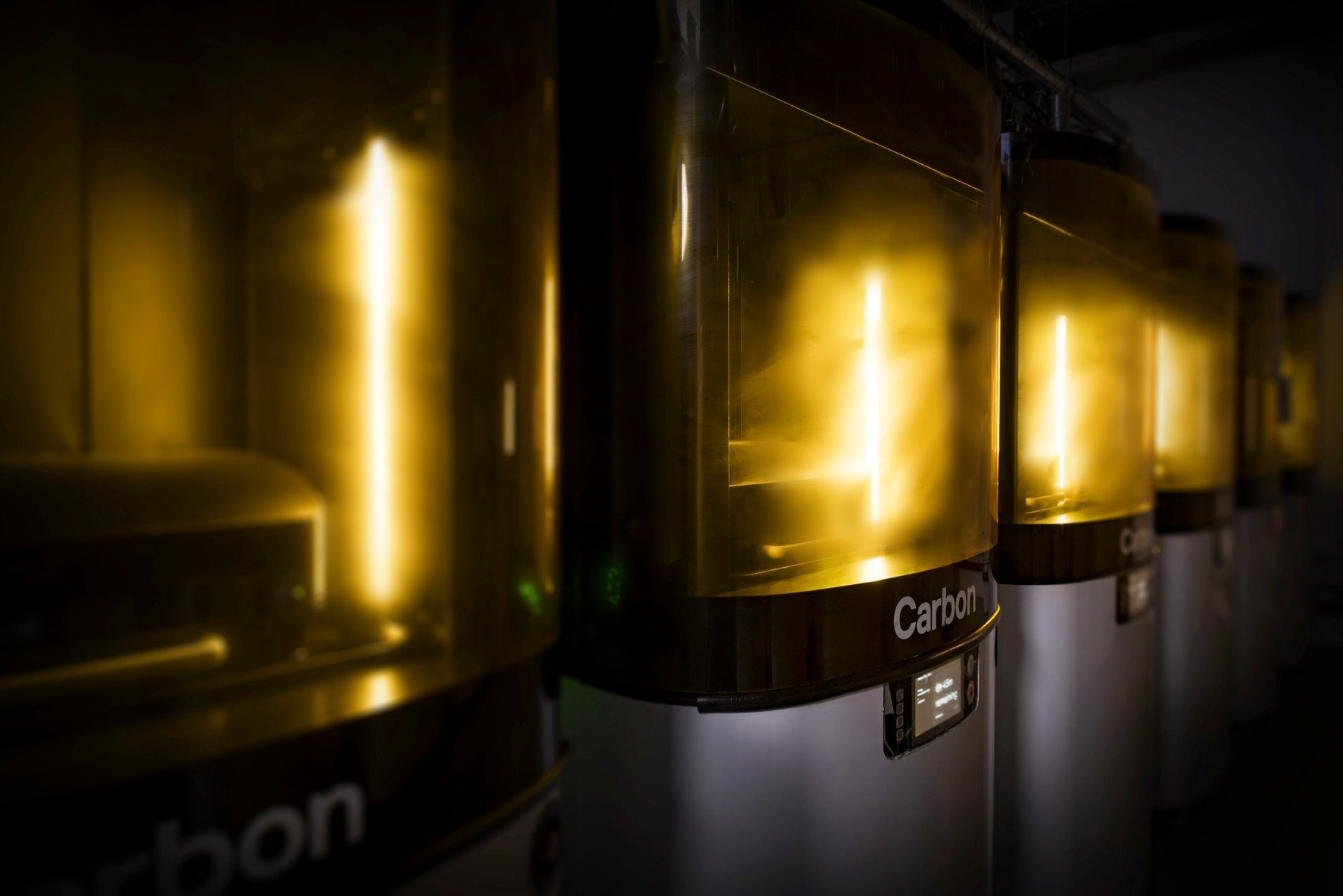

„ADDITIVE MANUFACTURING”: In this production process components are built in a 3D printer by depositing material one layer at a time, which gives us an option to optimise individual components very specifically in terms of ventilation, damping performance, stability or ergonomics.

We can now also create extremely complex and precise geometric shapes, which has previously not been possible in this form. An added little plus is that this manufacturing method only uses material that is ultimately required, so there is no waste.

In our technology partner OECHSLER, we have found one of the leading additive manufacturing specialists that has already made a name for itself in the area of 3D printed high-end products such as racing seats, athletics shoe soles and bike saddles. Together with OECHSLER, we have succeeded in revolutionising our proven AIR PAD SYSTEM in a fluid-based 3D printing process.

By directing UV light onto liquid resins and subjecting them to heat and surface treatment we have been able to optimise the manufacturing technology for our back pads, and can now set a new standard when it comes to back ventilation, damping performance and wearing comfort.

„ADDITIVE MANUFACTURING”: In this production process components are built in a 3D printer by depositing material one layer at a time, which gives us an option to optimise individual components very specifically in terms of ventilation, damping performance, stability or ergonomics.

We can now also create extremely complex and precise geometric shapes, which has previously not been possible in this form. An added little plus is that this manufacturing method only uses material that is ultimately required, so there is no waste.

In our technology partner OECHSLER, we have found one of the leading additive manufacturing specialists that has already made a name for itself in the area of 3D printed high-end products such as racing seats, athletics shoe soles and bike saddles. Together with OECHSLER, we have succeeded in revolutionising our proven AIR PAD SYSTEM in a fluid-based 3D printing process.

By directing UV light onto liquid resins and subjecting them to heat and surface treatment we have been able to optimise the manufacturing technology for our back pads, and can now set a new standard when it comes to back ventilation, damping performance and wearing comfort.

Highlights //

Features

360° VENTILATION

TOOL COMPARTMENT

HELMET CARRY

HYDRATION SYSTEM COMPARTMENT

MOBILE PHONE POCKET

NOTEBOOK POCKET

ORGANISER COMPARTMENTS

SEAMLESS SHOULDER STRAPS

HYDRATION CLIP

HIP BELT POUCH

KEY HOLDER

SIGNAL WHISTLE

SUNGLASS POCKET

#evocsports

EVOC COMMUNITY

Share your adventures using #evocsports and join the EVOC Community!